Weld Rigs For Sale: The Ultimate Guide to Choosing the Right One for Your Needs

The world of welding is vast and diverse, requiring specialized equipment for different applications. A cornerstone of mobile welding operations is the weld rig – a complete, self-contained welding setup typically mounted on a truck or trailer. Finding the right "weld rig for sale" can be a game-changer for your business, increasing efficiency, expanding your service area, and ultimately boosting your bottom line. But with so many options available, how do you navigate the market and choose the perfect rig for your specific needs?

Weld Rig For Sale

This comprehensive guide will walk you through everything you need to know about weld rigs, from understanding the different types and components to evaluating your requirements and making a smart investment. We'll also cover essential maintenance tips and address common questions to ensure you get the most out of your weld rig.

Why Invest in a Weld Rig?

Before diving into the specifics, let's consider the core benefits of owning a weld rig:

-

Mobility and Flexibility: The primary advantage is the ability to take your welding services directly to the job site. This eliminates the need to transport materials to a fixed location, saving time and money. Whether it's on-site repairs, pipeline welding, or construction projects in remote areas, a weld rig provides unmatched flexibility.

Increased Earning Potential: By offering mobile welding services, you can tap into a wider market and command higher rates. Clients are often willing to pay a premium for the convenience of having a welder come to them, especially for emergency repairs or time-sensitive projects.

-

Self-Sufficiency: A well-equipped weld rig is a self-contained unit, providing everything you need to perform welding operations without relying on external power sources or equipment. This independence is crucial in remote locations or situations where access to utilities is limited.

-

Professional Image: A clean, well-organized weld rig projects a professional image to your clients. It demonstrates that you are serious about your craft and committed to providing high-quality services.

Types of Weld Rigs: Choosing the Right Configuration

Weld rigs come in various configurations, each designed to suit specific applications and preferences. The most common types include:

-

Truck-Mounted Rigs: These are the most popular and versatile option. The welding equipment and supplies are mounted directly onto the bed of a pickup truck, providing a compact and mobile workstation. Truck-mounted rigs are ideal for general welding, repair work, and construction projects. Based on my experience, a one-ton truck with a heavy-duty suspension is typically recommended for carrying the weight of the equipment.

-

Trailer-Mounted Rigs: Trailer rigs offer more space and payload capacity than truck-mounted units. They are suitable for larger welding projects that require a wider range of equipment and supplies. Trailers can be customized to include storage compartments, generators, and even small workshops. Consider the towing capacity of your vehicle and the overall size of the trailer when making your selection.

-

Skid-Mounted Rigs: Skid rigs are designed to be transported by forklifts or cranes and are commonly used in industrial settings or on construction sites. They are not as mobile as truck or trailer rigs but offer a robust and durable solution for stationary welding operations.

Key Components of a Weld Rig

A well-equipped weld rig typically includes the following essential components:

-

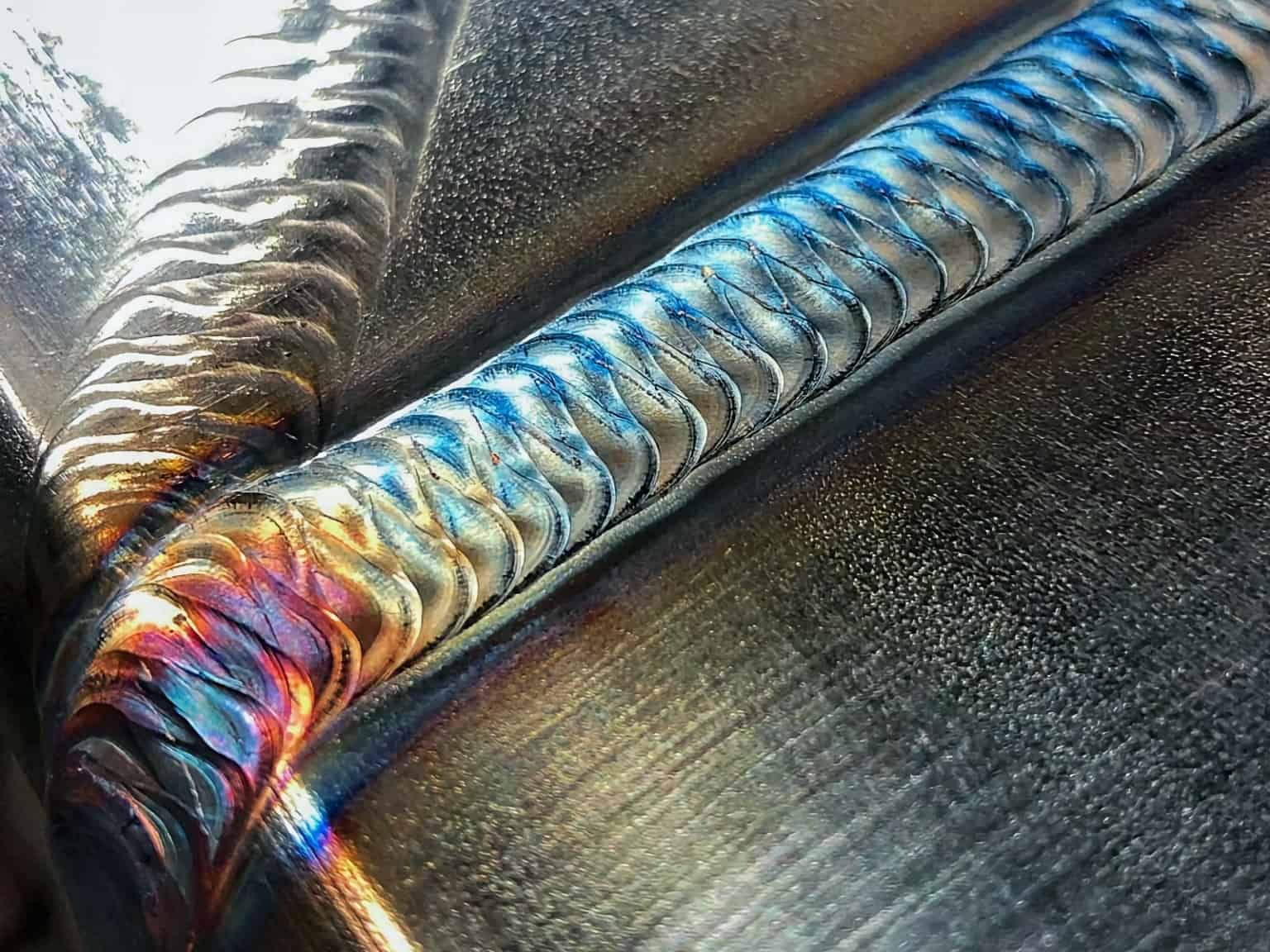

Welding Machine: This is the heart of the rig and should be chosen based on the types of welding processes you intend to perform (SMAW, GMAW, GTAW, etc.) and the materials you'll be working with. Consider the amperage output, duty cycle, and available features when selecting a welding machine. Pro tips from us, consider investing in a multi-process welder to handle a wider range of jobs.

-

Welder Generator: Provides electrical power to the welding machine and other equipment on the rig. Choose a generator with sufficient output to handle the combined power requirements of all your tools and accessories. Inverter generators are generally more fuel-efficient and quieter than traditional generators.

-

Gas Cylinders: Essential for gas-shielded welding processes such as GMAW and GTAW. The size and type of gas cylinders will depend on the welding processes you use and the frequency of your welding operations. Securely mount the cylinders to prevent accidents.

-

Welding Leads and Cables: These connect the welding machine to the workpiece and the electrode holder or welding gun. Choose high-quality leads and cables that are appropriately sized for the amperage output of your welding machine. Regularly inspect the leads and cables for damage and replace them as needed.

-

Hand Tools and Accessories: A comprehensive set of hand tools is essential for preparing the workpiece, making adjustments, and performing post-weld cleanup. This includes items such as welding helmets, gloves, chipping hammers, wire brushes, grinders, and measuring tools.

-

Storage Solutions: Proper storage is crucial for keeping your weld rig organized and preventing damage to your equipment and supplies. Consider investing in toolboxes, cabinets, and other storage solutions to maximize space and efficiency.

-

Safety Equipment: Safety should always be a top priority when welding. In addition to a welding helmet and gloves, you should also have safety glasses, earplugs, a fire extinguisher, and a first-aid kit readily available.

Evaluating Your Needs: What to Consider Before Buying

Before you start shopping for a "weld rig for sale," take the time to carefully evaluate your specific needs and requirements. This will help you narrow down your options and choose a rig that is perfectly suited for your business. Consider the following factors:

-

Types of Welding Processes: What types of welding will you be performing? SMAW (stick welding), GMAW (MIG welding), GTAW (TIG welding), or a combination of these? Choose a welding machine and accessories that are compatible with the welding processes you intend to use.

-

Materials You'll Be Welding: What types of materials will you be working with? Steel, aluminum, stainless steel, or other alloys? Different materials require different welding parameters and techniques.

-

Job Site Conditions: Where will you be using the weld rig? On construction sites, in industrial facilities, or in remote locations? Consider the terrain, weather conditions, and availability of power when choosing a rig.

-

Budget: How much are you willing to spend on a weld rig? Set a realistic budget and stick to it. Remember to factor in the cost of the rig itself, as well as any necessary accessories, maintenance, and insurance.

-

Size and Weight Restrictions: Are there any size or weight restrictions that you need to consider? For example, if you'll be working in confined spaces, you'll need a smaller, more maneuverable rig.

-

Storage Space: Where will you be storing the weld rig when it's not in use? Ensure that you have adequate storage space to protect the rig from the elements and prevent theft.

New vs. Used Weld Rigs: Weighing the Pros and Cons

When searching for a "weld rig for sale," you'll have the option of buying a new or used unit. Each option has its own advantages and disadvantages:

-

New Weld Rigs:

- Pros: New equipment, full warranty, latest technology, and customizable options.

- Cons: Higher initial cost, depreciation.

-

Used Weld Rigs:

- Pros: Lower initial cost, faster depreciation, readily available.

- Cons: Potential for hidden problems, limited warranty (or no warranty), outdated technology.

If you're on a tight budget, a used weld rig can be a good option. However, it's essential to thoroughly inspect the rig before you buy it. Have a qualified mechanic or welder inspect the equipment and look for signs of wear and tear, damage, or neglect. Ask for maintenance records and test the equipment to ensure that it's in good working order. Common mistakes to avoid are skipping the inspection and relying solely on the seller's word.

Where to Find Weld Rigs For Sale

There are several places where you can find weld rigs for sale:

-

Welding Supply Stores: Local welding supply stores often carry a range of weld rigs, both new and used. This is a good place to get expert advice and see the equipment in person.

-

Online Marketplaces: Websites like eBay, Craigslist, and Facebook Marketplace can be good sources for finding used weld rigs. However, be sure to exercise caution when buying online and thoroughly research the seller before making a purchase.

-

Equipment Dealers: Specialized equipment dealers often carry a wide selection of weld rigs, including custom-built units.

-

Auctions: Construction equipment auctions can be a good place to find deals on used weld rigs.

Maintenance Tips for Your Weld Rig

Proper maintenance is crucial for keeping your weld rig in good working order and extending its lifespan. Here are some essential maintenance tips:

-

Regular Inspections: Inspect the rig regularly for signs of wear and tear, damage, or leaks. Pay close attention to the welding machine, generator, hoses, cables, and safety equipment.

-

Fluid Checks: Check the oil, coolant, and fuel levels regularly and top them off as needed. Change the oil and filters according to the manufacturer's recommendations.

-

Cleaning: Keep the rig clean and free of debris. Clean the welding machine and generator regularly to prevent overheating.

-

Lubrication: Lubricate all moving parts regularly to prevent wear and tear.

-

Storage: Store the rig in a dry, secure location when it's not in use. Cover the equipment to protect it from the elements.

-

Professional Servicing: Have the rig professionally serviced at least once a year. A qualified technician can identify and address potential problems before they become major issues.

Conclusion

Investing in a weld rig can be a significant step for your welding business. By carefully evaluating your needs, researching your options, and following the maintenance tips outlined in this guide, you can choose a rig that will help you increase efficiency, expand your service area, and boost your bottom line. Remember to prioritize safety, and always use the appropriate personal protective equipment when welding.

Finding the perfect "weld rig for sale" requires careful consideration and planning. Take your time, do your research, and don't be afraid to ask questions. With the right rig, you'll be well-equipped to tackle any welding project that comes your way. Good luck, and happy welding!

[Internal Link to another relevant article on welding safety]